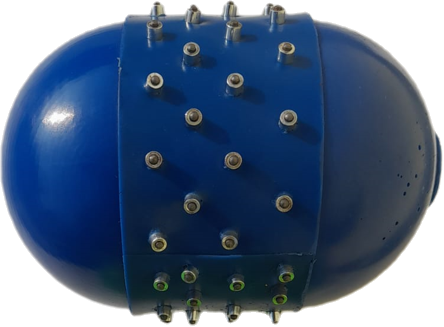

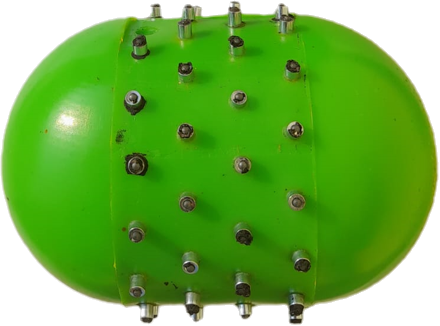

ARR Decoking Pigs

Northbound is pleased to offer ARR Decoking pigs. Stud and Pin pigs are widely recognized as the most effective method for thoroughly removing internal fouling, coke, scale, and other deposits from the inner surfaces of fired heater tubes, boiler tubes, and process piping. This advanced mechanical process is ideal for radiant coils in ethylene crackers (pyrolysis/steam cracking units), as well as refinery fired heaters in delayed cokers, crude distillation units, vacuum units, and similar applications.

Unlike traditional steam-air decoking, ARR specialized decoking scraper pigs are propelled by low-pressure water to deliver a superior clean—often returning tubes to a near-bare-metal or "like-new" condition.

Key Advantages

Superior Cleanliness — Removes virtually all coke, inorganics, scale, and obstructions for a smoother tube surface, reducing future fouling rates.

Extended Run Lengths — Achieves longer furnace operating cycles between decokes (with some operators reporting 10%+ improvements over steam-air methods).

Reduced Downtime — Typically faster than steam-air decoking, allowing quicker return to production and enabling concurrent maintenance activities.

Safer & More Reliable — Performed at ambient temperatures with no risk of tube overheating, hotspots, ruptures, or thermal stress.

Environmentally Friendly — Closed-loop system with no emissions venting to atmosphere; contained debris and optional water filtration for reuse.

Minimal Tube Damage — When executed properly, eliminates risks of internal erosion (especially in U-bends) compared to high-temperature methods.

Standard Features

Patented progressive scraper pigs — Engineered for optimal cleaning performance, with laminated construction combining strength and flexibility.

Full 360° coverage — Ensures complete circumferential cleaning, even in complex geometries.

Proven navigation — Designed to safely maneuver short-radius return bends, plug headers, mule ears, flat-back bends, and serpentine coils.

Bi-directional operation — Allows forward and reverse passes for thorough, controlled cleaning.

Low-pressure operation — Uses safe, low-pressure water propulsion (typically ~150 psi) via mobile pumping systems.

Near-new tube finish — Returns tubes to bare metal condition, outperforming steam-air decoking which may leave residual inorganics as fouling seeds.